We are SÜDLEDER.

And proud of it.

OUR Claim

We are SÜDLEDER and proud of it. This slogan represents everything that SÜDLEDER stands for. SÜDLEDER is characterised by tailor-made services paired with exclusive product quality. We receive global recognition for our high-quality tanning processes. We are passionate about sustainability, environmental responsibility and take a respectful approach to our most valuable material — leather. We are future-oriented and act conscientiously and sustainably. Each day, we aim to improve things for ourselves and future generations.

PHILOSOPHY

Leather has been around for thousands of years. Our work as a tannery is part of a natural cycle. Thanks to leather manufacturing, the skin and hide produced as a result of meat production is put to good use. Sustainability is a key part of our activities. We are convinced that premium quality can only be achieved through consistent economical and ecological behaviour. It is this belief which drives us to combine environmental protection and efficiency as effectively as possible. Our production processes are designed to fulfil their purpose safely and with minimal environmental impact. Careful treatment of valuable, natural resources is also a given for us.

BRAND VALUES

‘Made in Germany’ sustainable premium quality: this is what the SÜDLEDER brand stands for. Economical and ecological behaviour is our top priority. Sustainability is more than just a buzzword here. Sustainability is consistently implemented throughout our entire supply chain and valued company-wide.

SÜDLEDER perfectly combines environmental protection and cost effectiveness, creating safe production processes for people and the environment. Our use of natural resources is just as important as a respectful approach to our products.

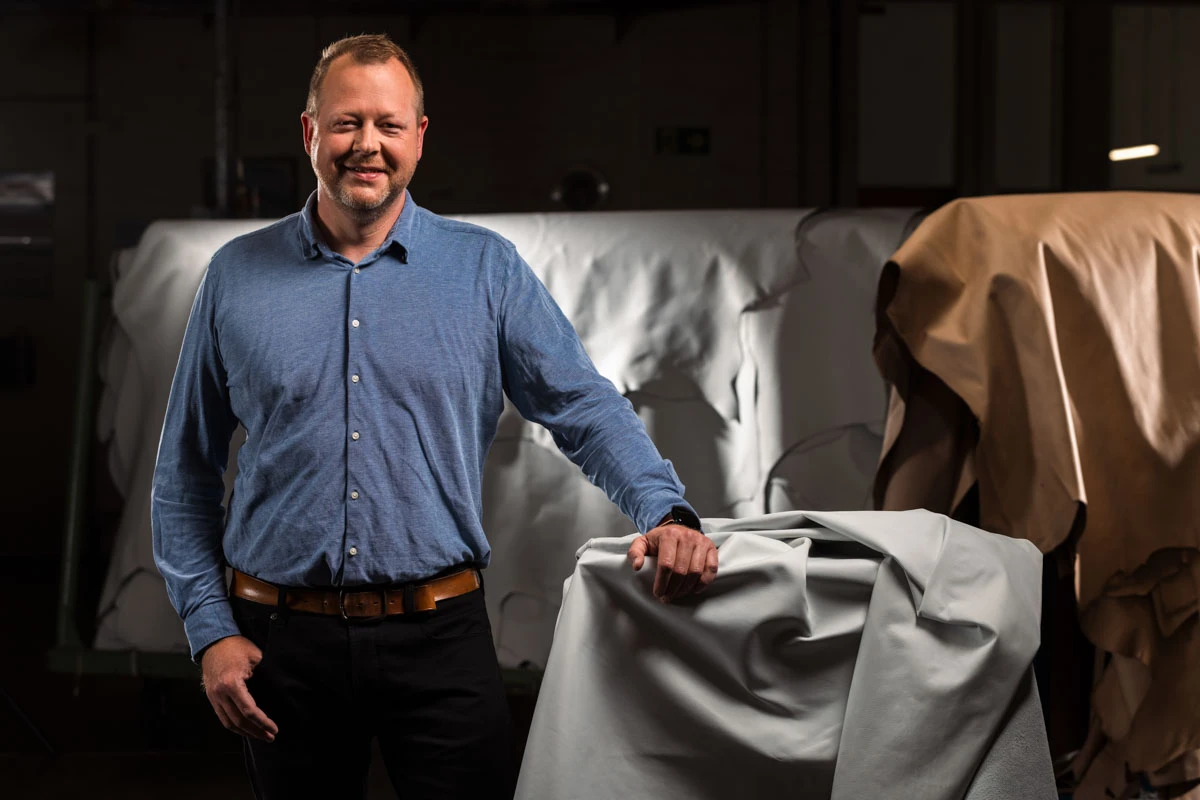

MANAGING DIRECTOR

Marcus Brinkmann

Marcus Brinkmann has a degree in Business Studies and has been a Managing Director at SÜDLEDER since 2016 and sole Managing Director since 2020. His previous experience with a renowned leather manufacturer for the automobile industry, where he worked for 15 years as Commercial Director and Managing Director, plus his experience with an international auditing firm form the basis for his professional career.

Team

Each day, our team of around 300 dedicated employees and specialists with years of expertise under their belt, ensure that all requirements are met and continually optimise them. We are SÜDLEDER. And proud of it. – This slogan reflects our commitment and passion for what we do. SÜDLEDER has been connecting people for generations.

History

Since 1979, SÜDLEDER has been producing premium leather for downstream manufacturers. The company headquarters have always been based in Rehau, a traditional tannery town with a long history of tanning. SÜDLEDER is characterised by its specialists with many years of know-how along with its constant search for innovation and new approaches. SÜDLEDER is one of the largest leather manufacturers worldwide. For decades, it has been a strong and reliable employer for almost 300 employees in the region.

1979

SÜDLEDER is founded in the traditional town of Rehau

1984

Acquisition of the company by J. Linhardt and E. Linhardt (Factory 1 and Factory 2)

1985

Purchase of the Rehau sewage plant for use as a process water treatment plant for SÜDLEDER

1995

Certification in accordance with DIN EN ISO 9001:1994

1997 - 1999

Construction of new storage and production facilities

2001

Expansion of hall and warehouse space for better processing of by-products

2003

Expansion of process water treatment plant capacity - innovative press technology

2007

Commissioning of new energy plant and limed fleshing processing

2010

New certification in accordance with DIN EN ISO 9001:2008

2011

Installation of new pipes for process water and gas Approval from the Federal Ministry for the Environment, Nature Conservation and Nuclear Safety (BMU) to improve company bioenergy plant

2012

Start of bioenergy plant construction. End goal: SÜDLEDER will achieve energy autonomy. Milestone is achieved. Plant test run successful - power is provided for the first time.

2013

Official commissioning of bioenergy plant

2014

Initial certification by the LWG Environmental Stewardship Audit

2015

Start of construction: Crust expansion

Certification in accordance with DIN EN 50001

2016

Change of management

New certification by the LWG Environmental

Stewardship Audit

Production in the new crust hall from May

2020

Ongoing modernisation and renovation of production machinery and plants to comply with the state of the art

2021

Start of new tannery management project, first construction phase successfully completed

Renewed LWG Gold certification

2022

The 2nd construction phase of tannery management is completed and put into service

Installation of new tanning and liming drums

2023

Installation of a completely new splitting line, the core of a tannery

The 3rd construction phase of tannery management is successfully completed

Renovation of tanning drums resumes

2024

The 4th and final construction phase of tannery control was successfully completed

Further barrel renewals in the tanning / liming and dyeing areas were carried out. A jumbo barrel was added for tanning, which has twice the capacity of our other tanning barrels.

LWG certification: Awarded gold again this year

We were awarded the German Brand Award 2024 in GOLD for our successful brand relaunch